There are 7 types packaging we need to design

Packaging design is one of the most important elements in the product packaging process. There are 7 types of packaging design available in the product packaging industry. Your brand has to feel like the perfect fit for the audience you’ve created it for. Getting your packaging design right is the most obvious way to achieve this and the first step on this journey is choosing between these 7 main types of packaging.

Packaging design comes in many different forms. It can be two colors or a set of colors that are easy to spot on the shelf and in store displays, or it can be fully branded with your company’s name and logo. There are other kinds of packaging design too, like special editions or limited-edition designs that you want only for certain products or occasions. Whatever kind of packaging you choose, make sure it accurately reflects who you are as a business so customers around the world will recognize your brand when they see it.

Packaging plays a large role in the perceived value of a product and as a whole, the packaging industry really hasn’t changed too much in the past years. With all the packaging and box choices available in today’s market, it often becomes difficult to select the most appropriate packaging solution for your product. Let’s take a look at some of these different types of packaging options:

1. Paperboard Packaging

Paperboard is one of the most common packaging materials used today, and has a variety of advantages. It is lightweight, easy to cut and manipulate, but can also be recycled at end of life. Paperboard packaging is a versatile, cost-effective and eco-friendly packaging material great for branding. Plastic or paperboard boxes are usually used as outer packaging such as display boards or shipping cases. These containers help protect products from damage during storage and transportation by keeping them fully protected during shipping and handling processes.

Paperboard boxes are both durable and cost effective, making them the ideal packaging material. They can be printed with your branding or design, adding an additional level of professionalism to your product. SBS (Solid Bleached Sulfate) paperboard is a type of paper product made from bleached sulfate pulp. It can be used to pack cosmetics, medicines, milk and juice, cosmetics, frozen food and more. Choosing kraft or CUK (Coated Unbleached Kraft) paperboard boxes for more environmentally friendly packaging applications where you want less resistance to moisture absorption, like food-related products or for frozen goods packaging.

2. Corrugated Packaging

Corrugated boxes are the very common and most common shipping, shoe & storage containers. Some people do not realize that corrugated boxes also come in different types depending on the durability and strength of the container. Identifying a certain corrugated material is easy. How do you determine the material? Through its corrugated medium (also known as fluting). The corrugated medium that gives it strength and rigidity through its flutes.

The corrugated board is a kind of material used in packaging. This kind of material is made by cutting, folding and blowing into a shape that can be used for many purposes. Corrugated boards are made from recycled paper pulp, which makes up about 50% of the board’s weight and gives it its unique look. The main raw material that is used to construct the corrugated board is most recycled paper, made on large high-precision machinery known as corrugators. These types of boards can reused and recycled again as a source of pulp fiber. Corrugated boards are one of the most common types used for packaging purposes due to their strength, recyclability and competitive price compared to other forms.

3. Plastic Packaging

Plastic is used in a wide range of products, including containers, toys, and packaging. Due to its low cost, durability and versatility, plastic has replaced many traditional materials such as wood, leather and glass.

Plastic packaging is a great choice for the efficient storage, transportation and preservation of food. This type of packaging has many advantages in which they can be recycled, and generally they are much more durable than paperboard boxes. Airtight plastic packaging containers can help to preserve the quality of food and eliminate any contamination issues. The US consumer spent $100 billion a year on aliment additives such as colorings, preservatives and flavorings; hence there is a need for safe products that help maintain health without harming natural environments or anyone’s health.

Plastic packaging is an option for many companies, especially for small to medium sized businesses. Plastic allows for a variety of shapes and sizes, so it’s easy to customize packaging designs to fit the product. It also helps prevent damage or shrinkage during shipping.

Plastic is not only recyclable, but it is also cost effective. In fact, according to the World Bank, plastic packaging costs about 50 percent less than glass packaging and 25 percent less than cardboard. Plastic also takes less energy to produce new than most other materials including paper and cardboard due to its high density.

4. Rigid Packaging

This type of box is known to be very durable, made with recycled paper and has a premium look that impresses everyone. It can hold any type of products such as mobile phones and other electronics appliances, jewelry, watches and clothing items. There are many companies that make these rigid boxes but one of the best ones is Paragon Packaging Company.

Rigid packaging is a very durable and high-quality packaging for your product. Rigid boxes are made out of highly condensed paperboard that is 4 times thicker than the paperboard used in the construction of a standard folding carton. Comparable to cardboard, rigid boxes are also quite cheap and easy to produce. We offer rigid boxes with your specific specifications in order to meet our customer needs.

Rigid packaging can be used in merchandising cosmetics, jewelry, technology, and high-end luxury couture. It is easy to incorporate features such as platforms and windows in a rigid box. With its high impact resistance and UV resistance, Rigid Packaging is ideal for durable goods that need to be transported on a regular basis.

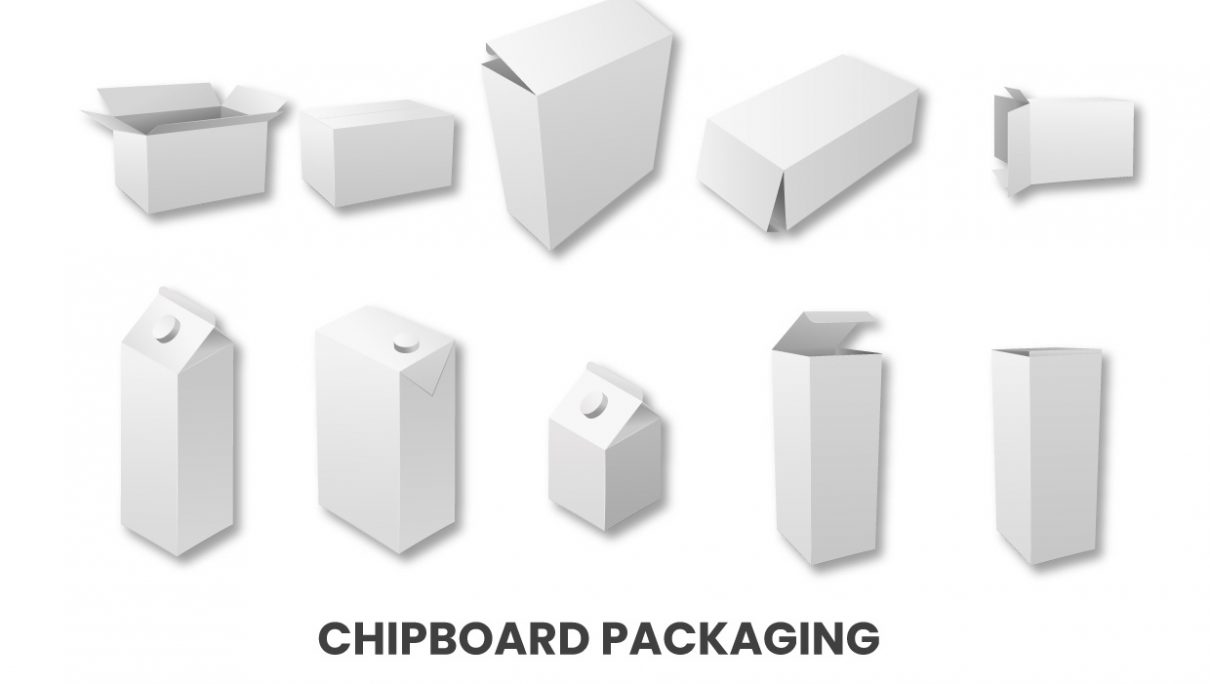

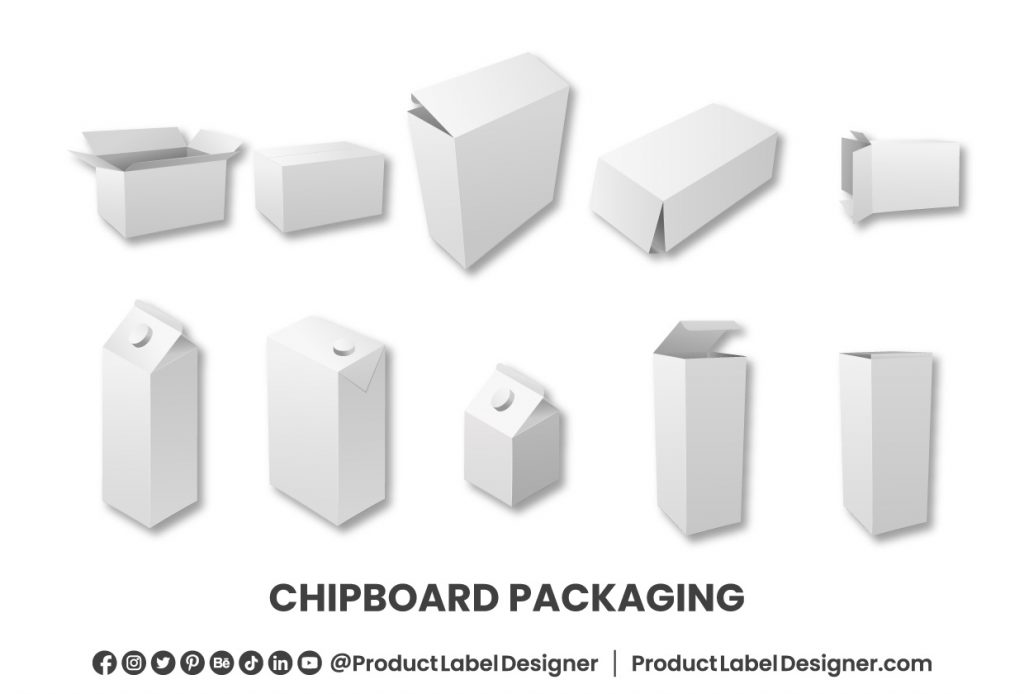

5. Chipboard Packaging

Chipboard packaging is a cost-effective way to package your products. Chipboard has a natural fall-off, which makes it friendly to the environment. It can be easily cut, folded and formed using standard paper cutter. Chipboard comes in various densities that are determined by how high its density is. This high density can also make it have a more durable surface compared with other chipboard materials. Chipboard can also be bleached with bleach sulfate or clay coated news back which make these papers even more resistant to tearing and scratching.

chipboard packaging can be used for many products, but it is not recommended for heavy items such as canned food, fragile linens and other types of textiles. Also, if the storage environment is heavy with moisture, chipboard can easily weaken, and result in discoloration and expansion.

6. Poly bags

Poly bags are one of the most common types of packaging, which can carry a wide range of products including food items, flowers, waste and chemicals. They are durable and flexible. Since poly bags are structurally simple to make, it can be fully customized in design or size but still remain cost-effective. Plastic recycling is also possible for this type of plastic film packaging material because even though it is flexible it’s not easily breakable by force. Most poly bags have security features like tape attachments, hanging holes and carrying handles so that items will be well secured while being visually appealing to customers.

With the help of poly bags, you are able to protect and carry items with ease. Poly bags can be used for food products as well as other valuable items such as electronics, cosmetics, clothes and more. Poly bags are durable, reusable and flexible which makes them perfect for a variety of packaging requirements.

7. Foil Sealed Pouch Bags

Foil sealed bags are used in the packaging industry to protect fragile products from damage. This can be seen typically in most coffee and tea packaging. Why? It keeps the products dense to maintain the flavor, protects it from bacteria coming in and helps increase shelf life. Apart from food, foil sealed bags are also used to package bedding and clothing products. The process involves removing the oxygen from the bag to keep the fabric tight and secure in order to prevent the growth of fungi. Nuts, cereals, smoked fish, cheese and cured meats are also packaged with foil sealed bags to prevent from spoilage.